BMA’s Toolbox

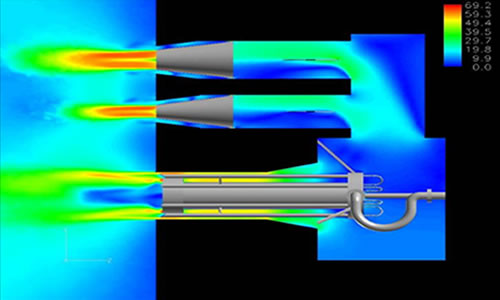

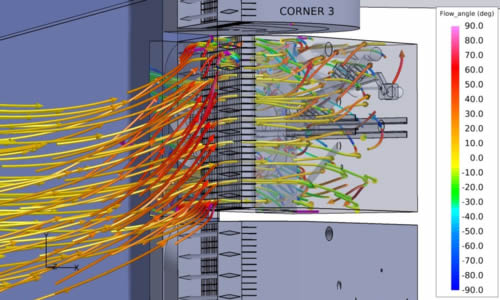

Computational Fluid Dynamics (CFD)

Numerical simulation is the tool which allows us to see inside the virtual black box that is industrial combustion.

In the case of thermal equipment (boilers, ovens, dryers, chimneys, heat exchangers, etc.), it can be extremely difficult to collect operational data due to the extremely high temperatures within.

Computational Fluid Dynamics (CFD) or Numerical Simulation is the key to unlocking this black box, and revealing the secrets that can be hidden within.

Our tool allows us to develop new concepts in a very precise way, thanks to modeling and simulation with digital mock-ups.

Using a framework of STAR-CD, STAR-CCM+ and other modeling platforms, our engineers have designed numerous custom software solutions to simulate a variety of combustion phenomena. Having full control over our tools in this way gives us the flexibility and adaptability needed to conduct customized studies.

Numerical simulation can reproduce:

- Flow and mixing of fluids (liquid and gas)

- Heat transfer and heat flux

- Combustion of a variety of fuels (gaseous, liquid and solid)

- Pollutant formation and concentration (CO, NOx, etc.)

- Effects of mixing and turbulence

- Dispersion of particles

- Boiling

- Two phase flow (oil, steam, air)

- Acoustics

Examples of situations where CFD is used

- Testing prototype performance prior to fabrication and industrialization.

- Solving scale-up problems: Simulations are run using the actual geometry of the equipment, rather than a reduced scale, as is often the case with analogue models.

- Eliminating costly trial and error thanks to virtual experimentation. This is ideal when the equipment in question must stay online, and is not available for testing.

- Providing data that is difficult to obtain in the field, due to the nature of the equipment, or to the difficulty of placing sensors. Ideal for identifying bottlenecks, and thus optimizing performance andproductivity.

- Improving equipment operation by testing performance prior to implementation. It’s no longer necessary to rely on empirical correlations – CFD allows us to recreate true behavior. For example; rather than relying on pressure drop correlations, CFD allows you to determine the actual pressure drop curve for your entire range of operations.

Examples of simulated systems

- Boiler (natural gas, oil, coal, biomass)

- Burner (low NOX, bi-fuel, pre-mix, etc.)

- Kiln

- Dryer

- Incinerator

- Heaters

- Furnace

- Flue gas and air system

- Wind Box

- Heat Exchanger

- HVAC system

- Desulphurisation tank

- Cooling Tower

- Turbine

- Pump

- Desuperheater

- Stack

- Wind Engineering

Analysis of water circulation in Boilers

BMA has developed its’ own specialized software to analyze the natural or assisted circulation patterns of water through boiler tubes.

BMA has developed its’ own specialized software to analyze the natural or assisted circulation patterns of water through boiler tubes.

Our software reproduces boiling and two-phase flow to provide information critical to boiler manufacturers and operators alike. Our model can predict flow conditions such as flow rate, velocity, quality, void fraction, heat transfer characteristics, flow pattern information, as well as the critical heat flux and anisothermality limits inside boiler tubes.

A boiler circulation analysis can help you to:

- Detect water leakage problems or boiler tube overheating which could lead to tube failure (leakage or rupture).

- Test and refine new designs quickly and economically before the manufacturing stage.

- Determine whether it’s possible to increase steam production without compromising the natural circulation of water through the boiler. BMA will then help you determine what changes are needed.

Prototype Test Lab

By allowing us to physically validate products at different stages of development, our workshop is the perfect complement to our engineering services and our modeling and numerical simulation tools.

Testing of developed concepts, prototypes, or existing systems are often extremely important to the design process, to fabrication, as well as to troubleshooting. In our workshop, we conduct rigorous tests and evaluations which can test the viability of a system, verify that it conforms to regulations, and pinpoint critical areas for improvement.

A few of the projects carried out in our lab:

- Design and fabrication of test benches

- Fatigue tests, durability tests, mechanical tests, electrical tests, etc.

- Fabrication and assembly of prototypes